Capabilities

Pallet Rack Systems

- A storage system that stores pallets of material in rows on metal shelves. The systems feature multiple levels of shelving that are accessible by forklifts. These systems are used to increase storage density by using vertical space.

- There are four main components of pallet racks. Those components are uprights, beams, pallet supports or wire decking, and row spacers.

- There are three primary types of racks: open frame racks, rack enclosures and wall-mount racks.

- NMC installs all types of pallet rack systems.

- Drive-In

- Push Back

- Pallet Flow

- Carton Flow

- A typical pallet rack compartment or cell can hold two pallets, each weighing 2,000 lbs., on a pair of beams, for a total of 4,000 lbs. To put this weight into perspective, it is like storing a Ford

F150 pickup truck.

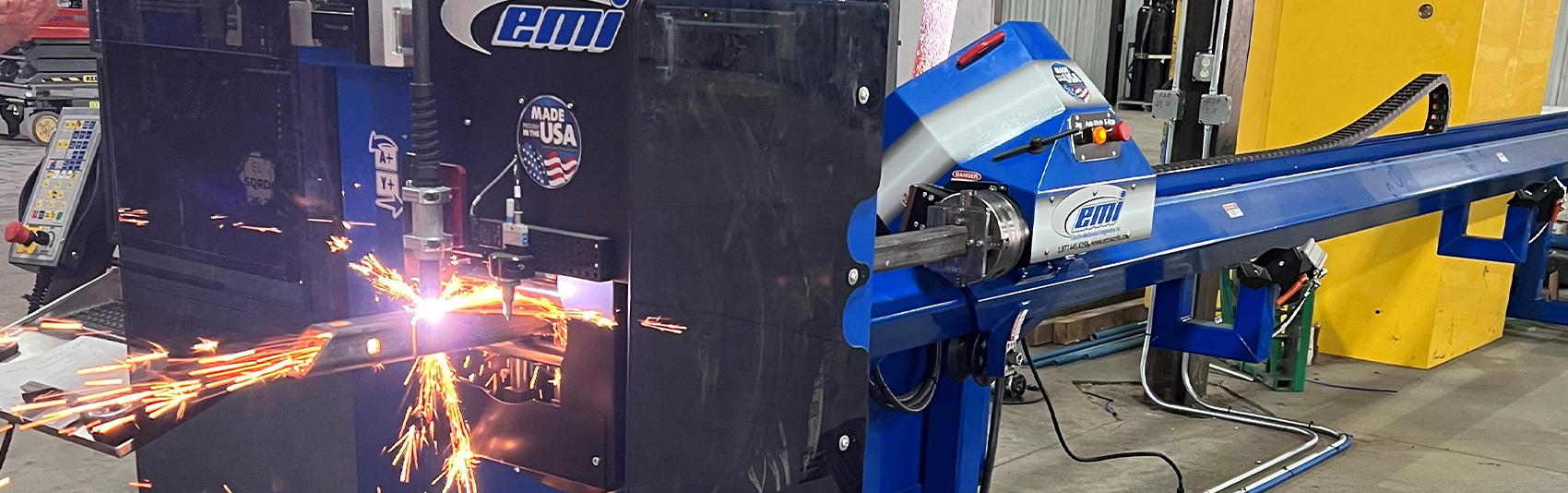

Fabrication

- There are three basic parts of steel fabrication – melting raw materials, mixing melted materials into steel, and forming the desired shape using said steel.

- Steel is one of the most desired materials in the construction industry, and it has a plethora of different appliances. The impressive toughness and other factors are the reason why steel components are used in pretty much anything, from transportation appliances to structures or entire buildings.

- Our top manufacturer offers a wide variety of steel fabrication services, with the ability to customize the details of each steel piece in accordance with the client’s wishes.

Powder Coating

- Powder coating is a dry finishing process that has become extremely popular since its introduction in North America over in the 1960s. Representing over 15% of the total industrial finishing market, powder is used on a wide array of products.

- Companies specify powder coatings for a high-quality, durable finish, allowing for maximized production, improved efficiencies, and simplified environmental compliance.

- Powder coated products are more resistant to diminished coating quality because of impact, moisture, chemicals, ultraviolet light, and other extreme weather conditions. In turn, this reduces the risk of scratches, chipping, abrasions, corrosion, fading, and other wear issues.

Relocation

- Moving metal construction materials on job sites can involve various operations such as lifting

and installing panels, stacking, or storing materials, and operating heavy machinery.- Forklifts, Telehandlers, Cranes are just some of the machineries our company uses for

material relocation.

- Forklifts, Telehandlers, Cranes are just some of the machineries our company uses for

Conveyor Platforms

- Conveyor Platform Installations are multi-level equipment platforms for a wide variety of

material handling including conveyor equipment. - All conveyer systems and accompanying industrial structures must be designed to support the

weight and stresses of the operating equipment as well as allowing for access to the equipment

for inspection and maintenance.